Common parameters of the serie:

Compressed air, which contains no trace of oil – Protects your system against oil contamination. Saves costly replacement of filter inserts for removing oil from air

Maximum reliability – The axial force is captured in the massive low-revolution bearings of the transmission, which avoids stress on the high-revolution bearings on the turbine shaft. They do not contain components subject to wear.

Contact-free seals. Unlimited services life of the oil bearings on the shafts. Low operating costs. The expected service life of the machine exceeds the service life of other types of turbo compressors several times.

Real option of idle running – Savings in energy and exceptional service life minimise costs for producing compressed air. Application of an input paddle system assures high operating efficiency throughout the year, even when the temperature of the intake air changes. Excellent efficiency even under part load. No sliding or rubbing components in the compression process, which would be subject to wear and cause reduced efficiency.

Easy maintenance – Do not contain components requiring regular replacement due to wear. Easy and quickly accessible, horizontally split transmission. Easily replaced and cleaned intercooler and aftercooler.

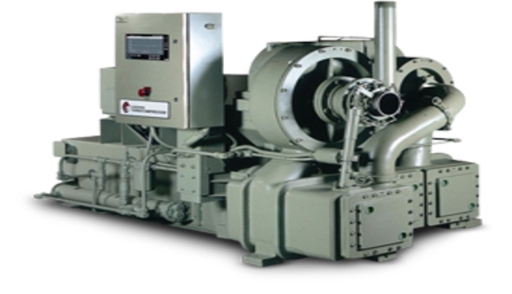

Simple installation – Compact, fully equipped compressor unit with aftercooler, Maestro Universal control system, electrical motor and lubrication system. Minimum external connections. Compact construction with minimum demands on built-on area. Does not require special foundations.